From Bottleneck to Breakthrough: Developing a Sustainable and Scalable Manufacturing Process for a Complex ADC Drug-Linker

2025 Peter J. Dunn Award for Green Chemistry & Engineering Impact in the Pharmaceutical Industry

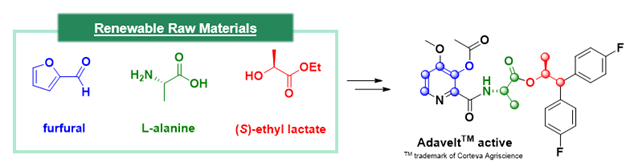

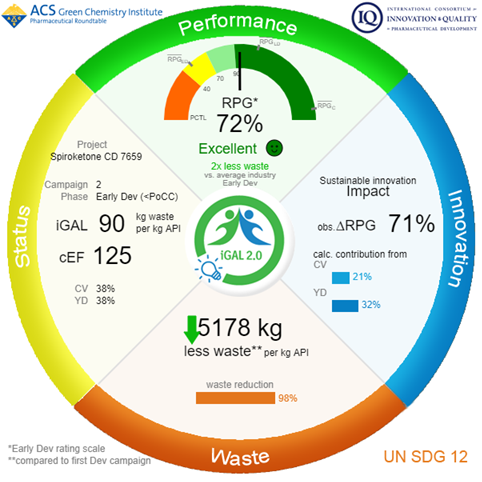

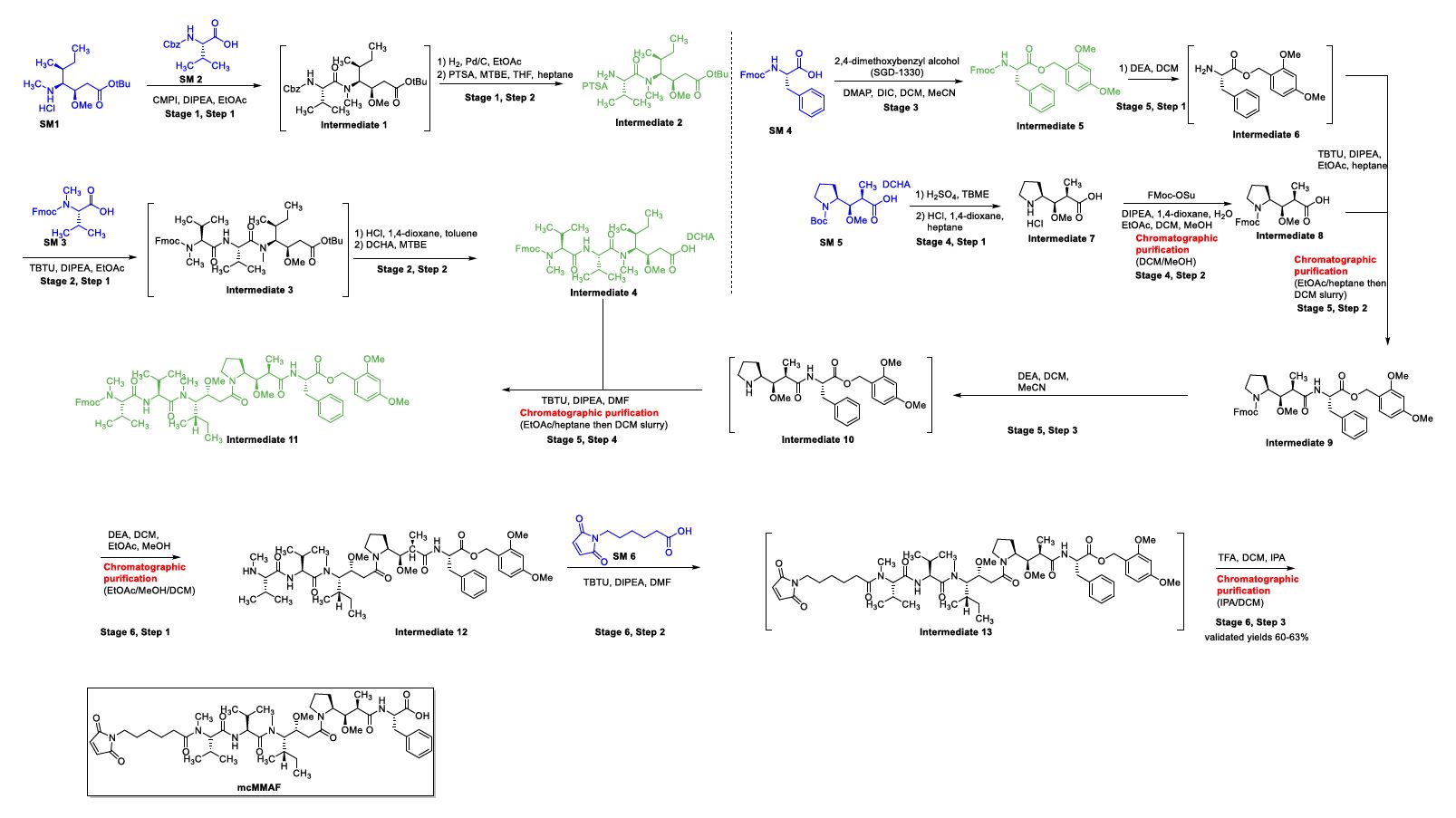

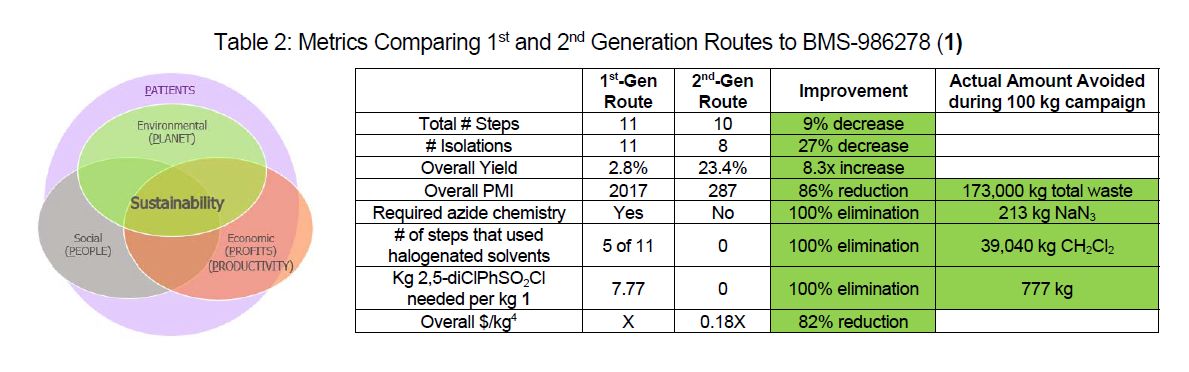

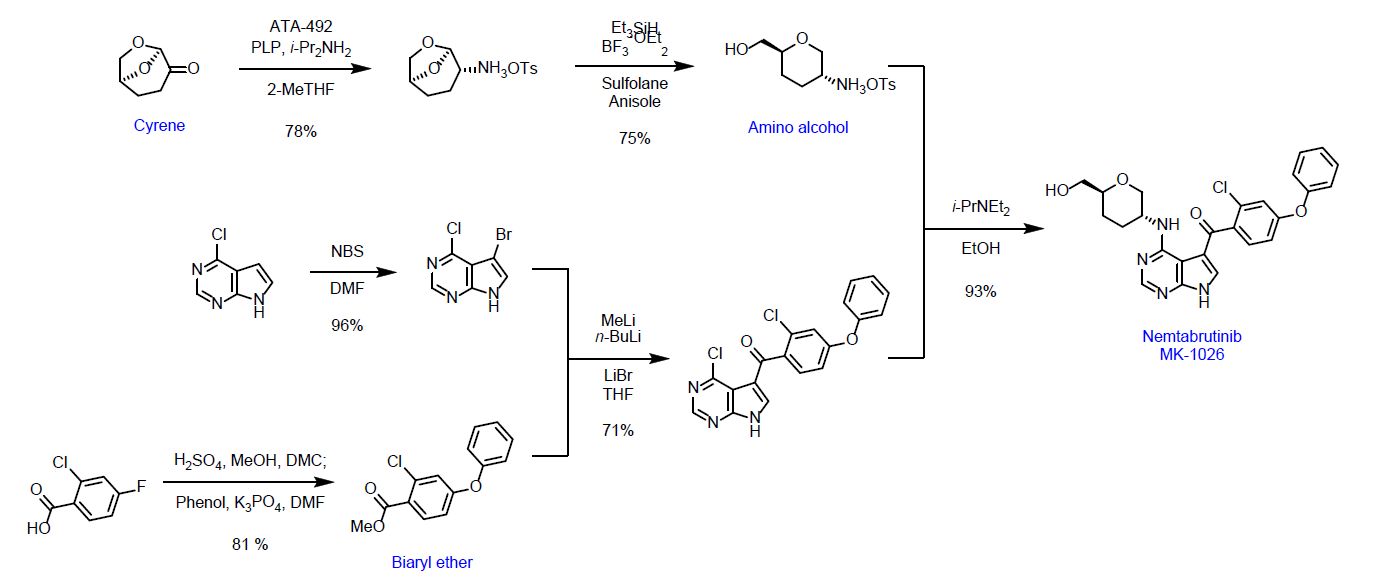

The Merck team, consisting of Patrick Fier, Patrick Moon, Scott McCann, Tao Liang, Greg Estrada, Marc Poirier, Reed Larson, Lu Wang, Gao Shang, and Fuh-Rong Tsay, received this award for their work, “From Bottleneck to Breakthrough: Developing a Sustainable and Scalable Manufacturing Process for a Complex ADC Drug-Linker”. They demonstrated the impact of applying green chemistry principles in the manufacturing process of the linker for the antibody-drug conjugate (ADC) Sacituzumab tirumotecan (MK-2870). Originally, the manufacturing process had long lead times due to the 20-step synthetic sequence and faced a major bottleneck with the final purification that limited production to less than 100 g per month even with 24/7 operation in a high-potency chromatography suite. Major improvements were achieved by developing a synthesis from a widely available natural product that cut seven potent steps down to three. The Process Mass Intensity (PMI) was reduced by approximately 75%, and the amount of energy-intensive chromatography time was decreased by >99% compared to the original route. This work highlights the advantages of investing in greener and more sustainable processes that naturally improve the global supply of medicines to patients.

More about the Award

The Peter J. Dunn Award, established in 2016, recognizes outstanding industrial implementation of novel green chemistry and/or engineering in the pharmaceutical industry that demonstrates compelling environmental, safety, cost, and/or efficiency improvements over current technologies.

This annual award is presented at the Green Chemistry & Engineering Conference, where presenters are invited to share their innovations.