Leveraging innovative manufacturing technologies to deliver sustainable processes: A production-scale continuous [2 + 2] photocycloaddition to prepare a key raw material

2022 CMO Excellence in Green Chemistry Award

The Inaugural CMO Excellence in Green Chemistry Award goes to Asymchem, located in Tianjin, China, for “Leveraging innovative manufacturing technologies to deliver sustainable processes: A production-scale continuous [2 + 2] photocycloaddition to prepare a key raw material.”

Asymchem developed a continuous gas-liquid biphasic photochemical cycloaddition of maleic anhydride with ethylene as a scalable and sustainable solution for the production-scale preparation of a pharmaceutically relevant cyclobutene derivative to be used as a key intermediate in an API synthesis for the partner pharmaceutical company Amgen. By working with the process design and by fabricating new equipment, Asymchem was able to reduce the number of synthetic steps by five, eliminate use of hazardous reagents, and reduce waste by 72% compared to the existing manufacturing route.

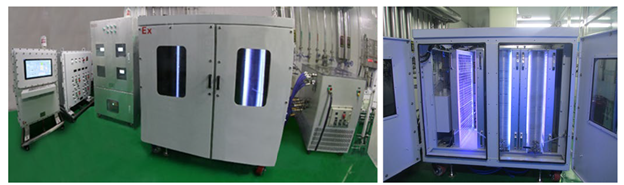

Caption: Pictures of the production-scale photochemical skid measuring ~2m tall, capable of producing 5 kg/day of cyclobutane. Photo credit: Asymchem.

More about the Award

The CMO Excellence in Green Chemistry Award seeks to recognize outstanding efforts by CMO companies in pharmaceutical green chemistry in support of pharmaceutical research, development, and manufacturing that demonstrate compelling environmental, safety, and/or efficiency improvements. The award recognizes greener advances in synthetic route development for starting materials, intermediates, or active pharmaceutical ingredients (APIs), including reaction conditions and chemical or manufacturing technologies.

This annual award is presented at the Green Chemistry & Engineering Conference, where a member of the winning team is invited to share their team’s innovations.

Pictured: Joshua Bolger, Senior Director of Process Chemistry at Asymchem, accepts the 2022 CMO Excellence in Green Chemistry Award from Isamir Martinez (ACSGCI) and ACS GCIPR 2022 Co-Chair, Philippa Payne of Gilead.