PMI Prediction and Bayesian Optimization: Two Tools with One Goal Towards the Development of ‘Greener-by-Design’ Synthesis of APIs

2024 Data Science & Modeling for Green Chemistry Award

The Bristol Myers Squibb team received the innaugral Data Sciences and Modeling Award for Green Chemistry award.

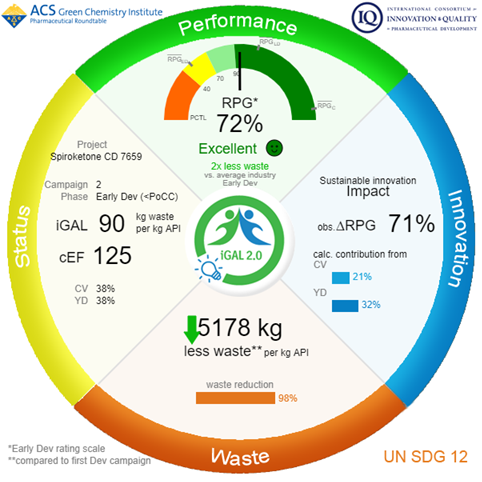

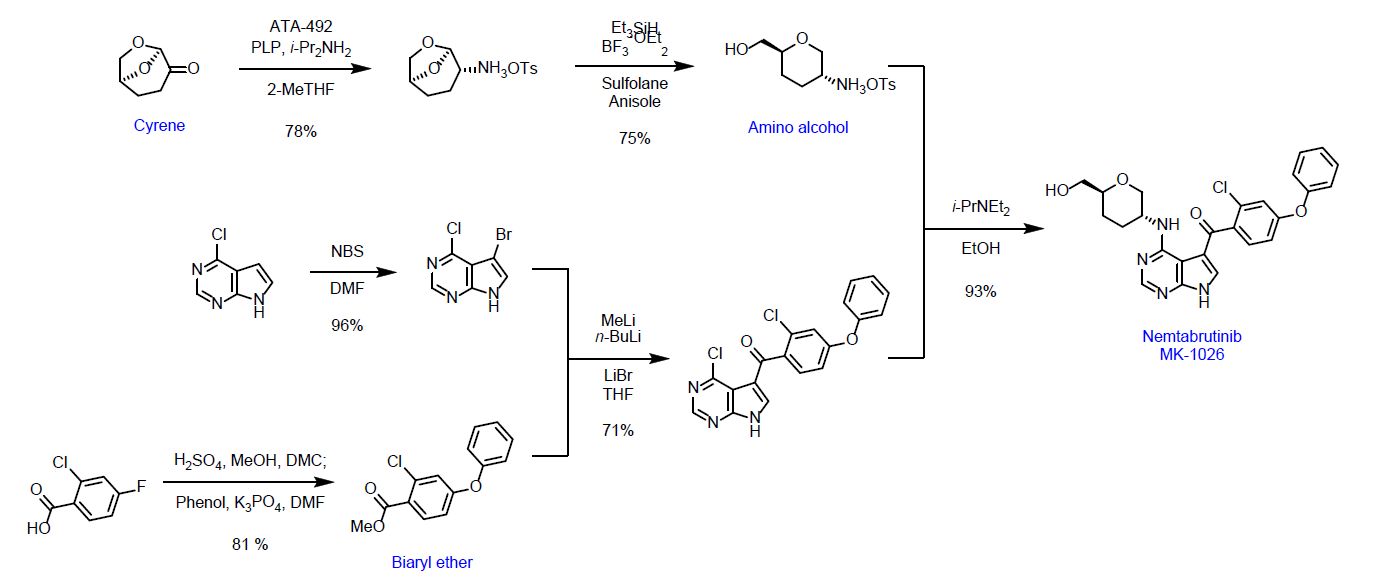

Richard Fox, Jun Li, Jacob Albrecht, Jason Stevens, Jose Tabora, Alina Borovika, and Benjamin Shields (BMS) partnered with Jose Garido (Princeton), Professor Ryan Adams (Princeton), and Professor Abigail Doyle (UCLA) to showcase two tools that are combined to arrive at greener processes during the design, development, and optimization of synthetic transformations. A process mass intensity (PMI) prediction app that utilizes predictive analytics and historical data of large-scale syntheses to help enable better decision-making during ideation and route design was coupled with a subsequent Experimental Design via Bayesian optimization application (i.e., EDBO/EDBO+) to accelerate the optimization of the subsequent individual chemical transformations was included. Taken together, these two tools enable process scientists to incorporate state-of-the-art open-access data science tools and algorithms into both defining their overall project strategies and conducting their daily laboratory experimentation to accelerate the advancement of “greener-by-design” outcomes.

Highlighting a real clinical candidate, the authors illustrated a quantitative method for the prediction of potential efficiencies centered around Process Mass Intensity (PMI) of proposed synthetic routes prior to their evaluation in a laboratory. This allows scientists to select the most efficient option prior to development and arrive at a holistically more sustainable chemical synthesis to a molecule moving into manufacturing. Following predictions for PMI across different synthetic sequences, the researchers rapidly identify the optimized conditions for a particular transformation using a machine learning Bayesian optimization (BO)n approach to explore chemical space and identify more sustainable reaction conditions with fewer experiments and resources. For the specific example included in their work, a process that yielded 70% yield and 91%ee through traditional one factor at a time (OFAT) using 500 experiments, was surpassed by the EDBO+ platform, providing 80% yield and 91%ee in only 24 experiments. Both technology platforms are open source and available for researchers at no charge, increasing the potential for adoption and use by others.

More about the Award

The Data Science and Modeling for Green Chemistry award recognizes innovation or excellence in the research and development of computational tools that empower users to effectively design, implement, and evaluate green processes with reduced process mass intensity, waste, health and safety impact, and other aspirational improvements. The award was open to both academic and industrial applicants, and a number of excellent nominations were received for consideration.

This annual award is presented at the Green Chemistry & Engineering Confernece where presenters are invited to share their innovations.

Pictured: Jason Stevens, Associate Scientific Director at BMS, accepts 2024 Pete Dunn Award from Isamir Martinez (ACSGCI) and ACS GCIPR 2024 Co-Chair, Dan Bailey of Takeda.